Auto bumpers are more than just decorative features—they serve as the first line of defense in protecting vehicles and occupants from collisions. Auto bumper molds are engineered to create bumpers that absorb and distribute impact energy, minimizing damage to the vehicle's structure and reducing the risk of injury to passengers. Each aspect of the mold design, from the materials used to the shape and thickness of the bumper, contributes to its ability to safeguard lives.

Precision Engineering: Crafting Durability and Functionality

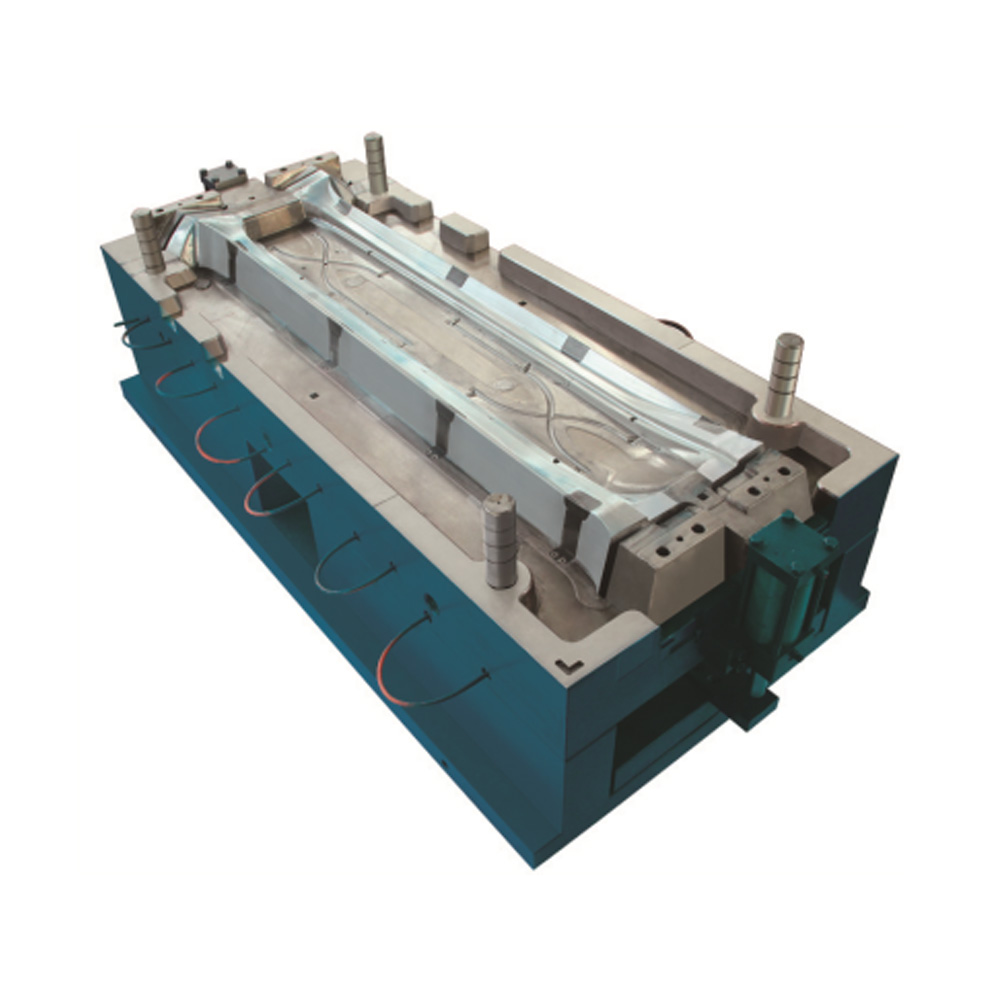

The creation of high-quality auto bumpers begins with meticulous mold design. Auto bumper molds are intricately crafted to ensure the precise shaping of the bumper's curves, angles, and contours. These design nuances influence the bumper's aerodynamics, structural integrity, and compatibility with other vehicle components. The precision engineering of auto bumper molds results in bumpers that not only enhance safety but also contribute to the vehicle's overall performance.

Design Freedom: Innovation in Automotive Aesthetics

Auto bumper molds also play a pivotal role in shaping the visual identity of vehicles. The design flexibility offered by these molds allows automakers to experiment with various styles, textures, and surface finishes. Whether it's a sleek, sporty look or a refined and elegant design, auto bumper molds empower designers to translate their creative visions into tangible automotive features that resonate with consumers.

Material Selection: Balancing Strength and Sustainability

Modern auto bumper molds accommodate a range of materials that balance strength, durability, and environmental responsibility. From traditional metals to advanced engineering plastics, the choice of material impacts the bumper's performance, weight, and ecological footprint. The use of lightweight yet robust materials in auto bumper molds contributes to improved fuel efficiency and reduced emissions while maintaining the necessary safety standards.

Crash-Tested Reliability: Ensuring Performance Under Pressure

Auto bumper molds contribute to the development of bumpers that undergo rigorous crash testing to ensure their performance under real-world collision scenarios. These tests evaluate factors such as impact absorption, structural integrity, and occupant protection. The precision and consistency achieved through auto bumper molds play a significant role in producing bumpers that meet and exceed safety regulations.

Sustainable Solutions: Driving Environmental Responsibility

The automotive industry's growing emphasis on sustainability has prompted advancements in auto bumper molds that support eco-friendly practices. Many manufacturers are adopting recycled and bio-based materials in bumper production, and auto bumper molds are designed to accommodate these materials. By integrating sustainable options, auto bumper molds contribute to reducing the environmental impact of automotive manufacturing.

Streamlining Production: Efficiency and Cost-Effectiveness

Auto bumper molds streamline the production process by enabling the rapid creation of uniform bumpers. Injection molding techniques, commonly used with these molds, allow for efficient production with minimal variations. The precision and consistency achieved through auto bumper molds contribute to cost savings, reduced waste, and increased production output.

English

English 日本語

日本語 Français

Français Deutsch

Deutsch Español

Español 简体中文

简体中文

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>(canaddletterfordraptor)-1.jpg) View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>