In the ever-evolving automotive enterprise, Huangyan constantly is seeking progressive methods to enhance the aesthetics and capability of motors. One such element that plays a vital position in reaching this stability is the automobile side skirt mildew. This indispensable aspect not handiest contributes to the visual appeal of an automobile but also serves sensible purposes. In this text, we will delve into the world of car side skirt moulds, exploring their design, production processes, and the effect they have on car performance.

Auto side skirts are aerodynamic components placed alongside the lower edge of a car's facets, going for walks among the front and rear wheel arches. These moulds aren't merely decorative; they serve a dual reason of improving the automobile's aerodynamics and including a touch of fashion.

One of the primary functions of auto side skirt moulds is to improve the aerodynamics of a car. By reducing air turbulence and directing airflow more correctly alongside the car's facets, facet skirts a contribute to decreased drag. This, in flip, complements fuel performance and overall overall performance. Additionally, properly designed side skirts can help stabilize the car at better speeds, enhancing dealing with an avenue grip.

Beyond their useful advantages, car side skirts are a key detail in automobile layout. They can drastically decorate the visual enchantment of an automobile, giving it a sportier and extra-aggressive appearance. Auto manufacturers often use facet skirts to create a cohesive and dynamic outside layout that displays the brand's identity and resonates with purchasers.

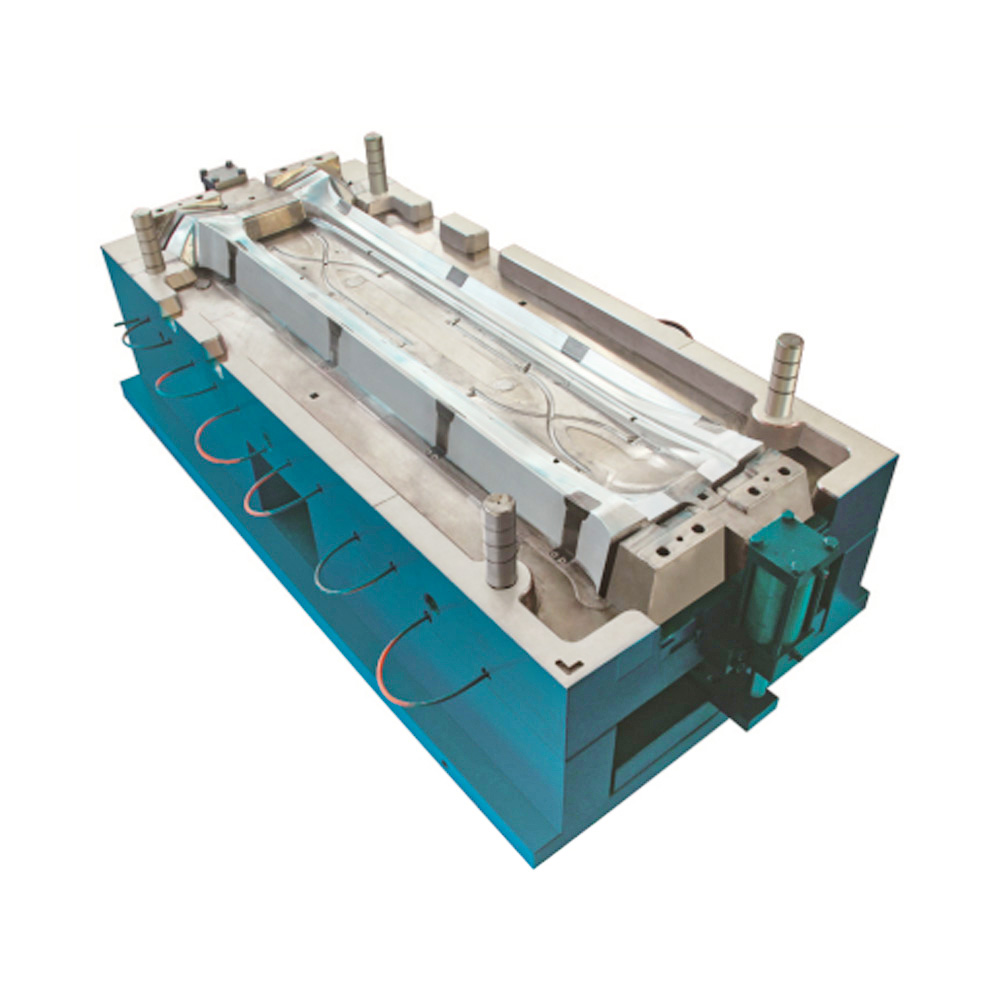

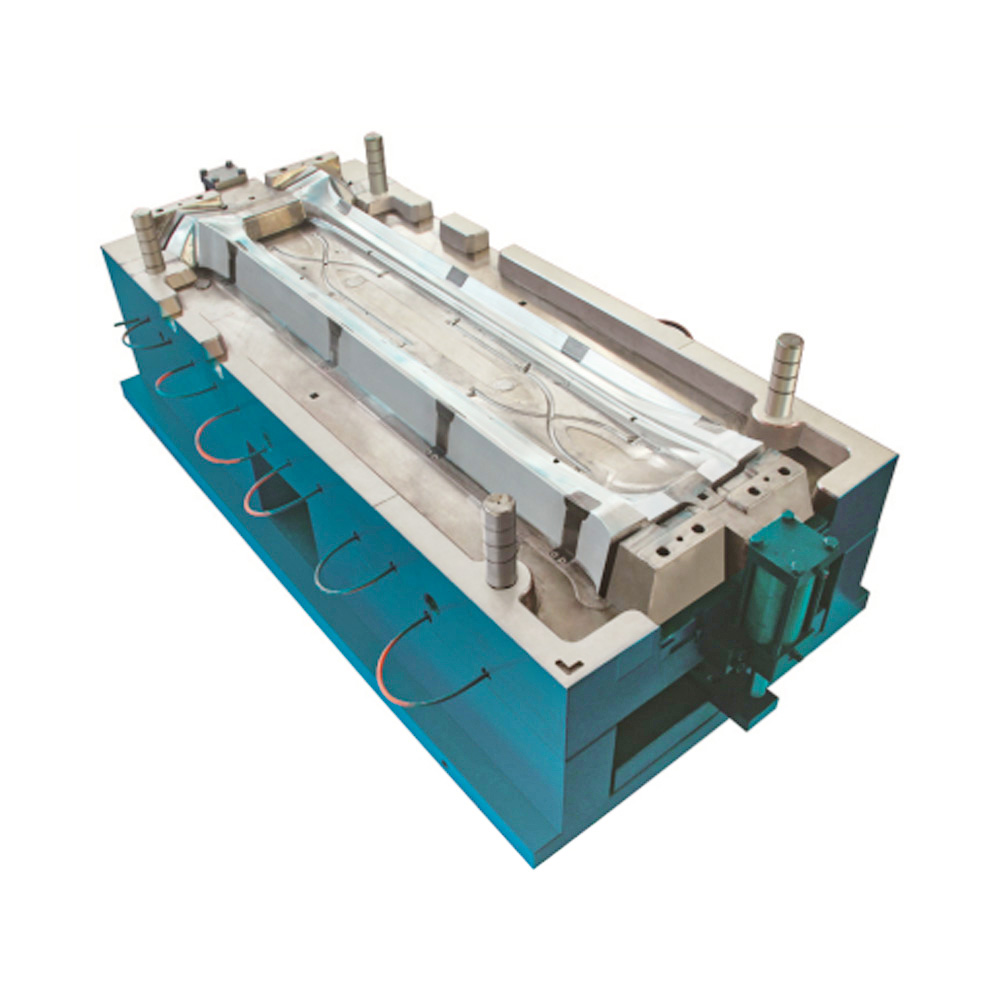

The design of car side skirt moulds involves careful stability among aesthetics and aerodynamics. Engineers and architects collaborate to create moulds that seamlessly integrate with the automobile's standard design at the same time as making sure surest aerodynamic overall performance. Factors which include fabric selection, shape, and length are meticulously taken into consideration to gain the desired balance.

Auto aspect skirt moulds are commonly made from lightweight yet long-lasting substances consisting of ABS plastic, fiberglass, or carbon fiber. These substances offer the essential energy with out adding immoderate weight to the automobile. The production system includes precision molding techniques, with manufacturers the usage of advanced technologies like injection molding or compression molding to create the tricky shapes required for effective aspect skirts.

The reputation of vehicle aspect skirts has led to a thriving aftermarket industry. Car fanatics and proprietors often searching for to customize their cars with unique side skirt designs to stand out on the road. Aftermarket vehicle aspect skirt moulds are to be had in various shapes, sizes, and substances, allowing individuals to personalize their automobiles in step with their possibilities.

Auto side skirt moulds have ended up an essential part of the modern automotive layout, seamlessly mixing fashion with capability. As vehicles continue to evolve, those aerodynamic components will in all likelihood play an even more crucial function in achieving the surest overall performance and a specific appearance on the road. Whether integrated into the unique layout or delivered later through aftermarket alternatives, car aspect skirts contribute to the ever-developing synergy between aesthetics and engineering in the car international.

English

English 日本語

日本語 Français

Français Deutsch

Deutsch Español

Español 简体中文

简体中文

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>(canaddletterfordraptor)-1.jpg) View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>